World's First and Only by BASF: Macrosynthetic Fiber with Chemical Bond to Concrete!

A truly unique and performance-enhancing macrofiber to make life easier for concrete producers and contractors while greatly enhancing concrete performance and durability!

What are Macrofibers?

Macrofibers have been developed to replace welded-wire reinforcement and reinforcing bars that are typically used to control temperature and shrinkage cracking.

Fibers are used to reduce crack width typically due to plastic shrinkage, long term drying shrinkage and thermal changes. Because concrete cannot be prevented from cracking, the goal is to mitigate and keep the cracks tightly closed. This in turn helps ensure long-term durability, and provides increased service life.

For higher performance, however, more fibers are required, which, inevitably increases the mix adjustment requirements.

The Breakthrough!

BASF sets a new standard for fiber-reinforced concrete with MasterFiber MAC 2200 CB.

The new fibers provide post-crack performance equal to that obtained with typical, commercially available synthetic macrofibers at a lower fiber dosage. The benefits of lower fiber dosage include greater concrete workability and easier placement, improved fiber dispersion and mix design optimization.

The superior performance of MasterFiber MAC 2200 CB is achieved using a novel resin technology. The resin provides engineered, chemical bonding between the fiber surface and cement matrix of the concrete; a technology breakthrough from BASF. Through this advanced technology and a highly engineered fiber architecture, the bonding capabilities of MasterFiber MAC 2200 CB far exceed that of the other commercially available synthetic macrofibers.

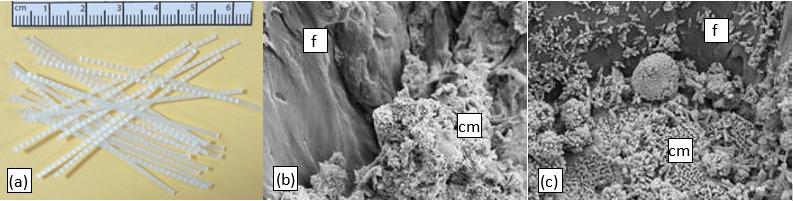

(a) MasterFiber MAC 2200 CB filaments; Scanning Electron Microscope (SEM) micrographs for: (a) reference fiber; and (b) MasterFiber MAC 2200 CB (Note: f is fiber; cm is cementitious matrix)

The MasterFiber MAC 2200 CB product is recommended for use in cast-in-place and wet precast concrete, slab-on-ground, bridge decks, concrete pavements and white topping and overlays.

Slab joint failure is the number one maintenance problem in high traffic facilities such as airport runways/taxiways, slabs-on-grade, industrial facilities with dense forklift traffic etc... MasterFiber MAC 2200 CB increases the post-crack load carrying capacity and toughness of fiber-reinforced concrete. This allows for extended joint spacing and reduced number of slab joints, thus less maintenance and less cost associated with maintenance.

Watch our video for more on how MasterFiber MAC 2200 CB works.

Get the optimum dosage

Master Builders Solutions provides chemically bonded fiber reinforced concrete mix-design support to Consultants, Concrete Manufacturers, and Contractors by the appointment of Mr. Hamzah Najjar.

Mr. Najjar has joined BASF Construction Chemicals UAE LLC as the Innovation Sales Manager, responsible for implementing the correct usage of fiber reinforced concrete, anti-microbial admixtures, corrosion inhibitors, and crystalline waterproofing admixtures.

Prior to this role, he was working for BASF Corporation Admixture Systems in North America as a Senior Technical Support & Specifications Engineer.

Mr. Najjar has worked on over 1,000 projects for the use of synthetic and steel fibers, helping to form solutions to conventional steel reinforcement for all types of applications including: slabs-on-ground, composite metal decking, septic tanks, burial vaults, extended joint spacing and a variety of other applications.

What's in it for you!

Concrete professionals can take advantage of either higher performance when you use the same dosage as standard macrofiber, or same performance when you use lower dosage than standard macrofiber:

| Higher Performance - Same Dosage | Same Performance - Lower Dosage |

| Tighter crack control | Better workability |

| Extended joint spacing | Easier movement |

| Improved load transfer at contraction joints | Fewer adjustments |

| Slab thickness reduction | Improved fiber dispersion |

The overall benefits of using MasterFiber MAC 2200 CB are:

- Reduced dosage, therefore reduced cubic meter cost of concrete.

- Eliminates the need for welded-wire reinforcement (WWR) and conventional steel bars as secondary reinforcement, depending on the application. No more rusting.

- Effective tight crack control.

- Extends service life with reduced maintenance.

- Faster speed of construction and time savings.

- Overall labor and material savings.

- Improved worker safety.

BASF offers a comprehensive line of MasterFiber products for every level of reinforcement:

- Level 1: Control of plastic shrinkage cracking - MasterFiber microsynthetic monofilament fibers

- Level 2: Post-crack control and replacement of traditional shrinkage and temperature reinforcement - MasterFiber macrosynthetic fibers

- Level 3: Partial or complete replacement of structural steel reinforcing bars - MasterFiber macrosynthetic fibers

We're here for you! Please contact us to learn more about our fibers and how it can benefit your next project!

Stay Connected…