Green Sense Concrete

Concrete - The Key to Sustainable Construction

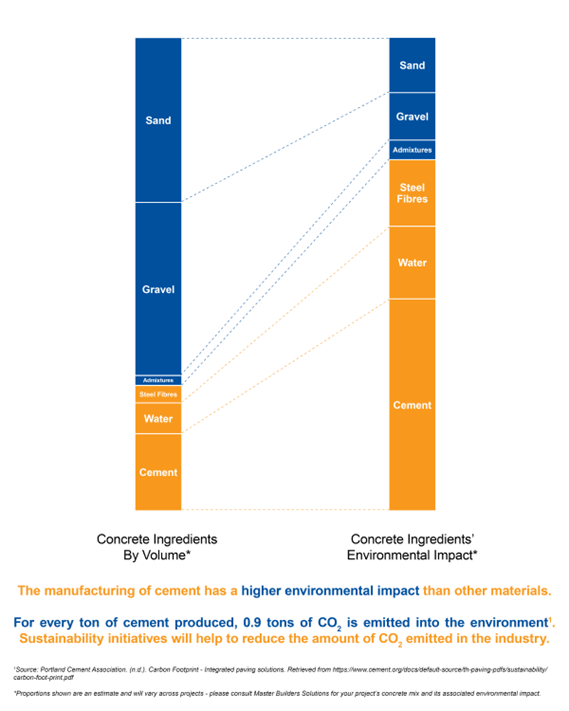

The environmental impact involved in the production of concrete must be acknowledged and addressed. For example, the manufacturing process for the cement used in concrete generates approximately 8% of global CO2 emissions. Sustainability has become a key issue in the construction sector and Master Builders Solutions is promoting the development of innovative solutions to answer today’s urgent questions.

Green Sense Concrete - A Sustainable System

- Optimized mixture program that incorporates waste streams from other industries such as fly ash, silica fume, slag (GGBFS), metakaolin, manufactured sand, crushed stone dust etc.

- Optimized formulations of concrete mixtures that contain a high proportion of recycled materials.

- A quantified decrease in the carbon footprint and environmental impact of concrete and hence, new buildings.

- Extended life cycles of existing buildings.

What is Included in the Green Sense Concrete System

- A selection of our innovative admixture products such as

MasterEase,

MasterGlenium SKY,

MasterGlenium ACE, MasterMatrix and

Master X-Seed etc. These solutions enable to decrease cement and water content in the mix and accommodate for recycled materials in concrete.

- Concrete mix services to increase the amount of supplementary cementitious materials.

- An eco-efficiency analysis tool that evaluates and compares similar concrete products for sustainability based on life cycle assessment and costs. This tool can be utilized through Master Builders Solutions.

Benefits of the Green Sense Concrete System

The Green Sense Concrete system is optimized for performance and many tangible benefits can be realized.

For the Owner/Developer

- Ensures a durable, low maintenance cost structure with extended service life.

- Attain sustainability credits from green bodies such as LEED etc.

- Increases valuation and early realization of the property.

For the Contractor

- Early handover of projects.

- Optimized use of resources in construction.

- Simplifies and speeds up concrete installation, saving time and money.

For Concrete Producers

- Optimized use of supplementary cementitious materials.

- Reduced cement content.

- Better control of setting time, slump retention, and strength leading to less concrete rejection.

- Optimized production costs.

For Specifiers

- Adds value to the building by quantifiably improving its sustainability credentials.

- Provides specification data on the eco-balance of concrete.

For Environmental Agencies or Communities

- Less cement, CO2, or energy used per unit of concrete produced.

- Less by-product materials targeted for landfill.

- Lower water consumption at construction sites.

- Lower consumption of natural resources such as groundwater and sand.

Our Construction Solutions at a Glance

/Functions_FLOORING.jpg)

/Functions_GROUTING.jpg)

/Functions_INNOVATIONS.jpg)

/Functions_PRODUCING_CEMENT.jpg)

/Functions_PRODUCING_CONCRETE.jpg)

/Functions_PROTECTING_CONCRETE.jpg)

/Functions_REPAIRING_CONCRETE.jpg)

/Function_Underground-Construction.jpg)

/Functions_WATERPROOFING_AND_SEALING.jpg)