Returned Concrete Recycling, Made Easy

Returned concrete has always represented a significant challenge for ready-mixed concrete suppliers, logistically, financially and environmentally. Regardless of whether it’s processed through a mechanical recycling system, used for blocks, stockpiled for crushing, or simply disposed of at landfill - dealing with returned fresh concrete is both time-consuming & expensive.

In 2022, all of this is changing.

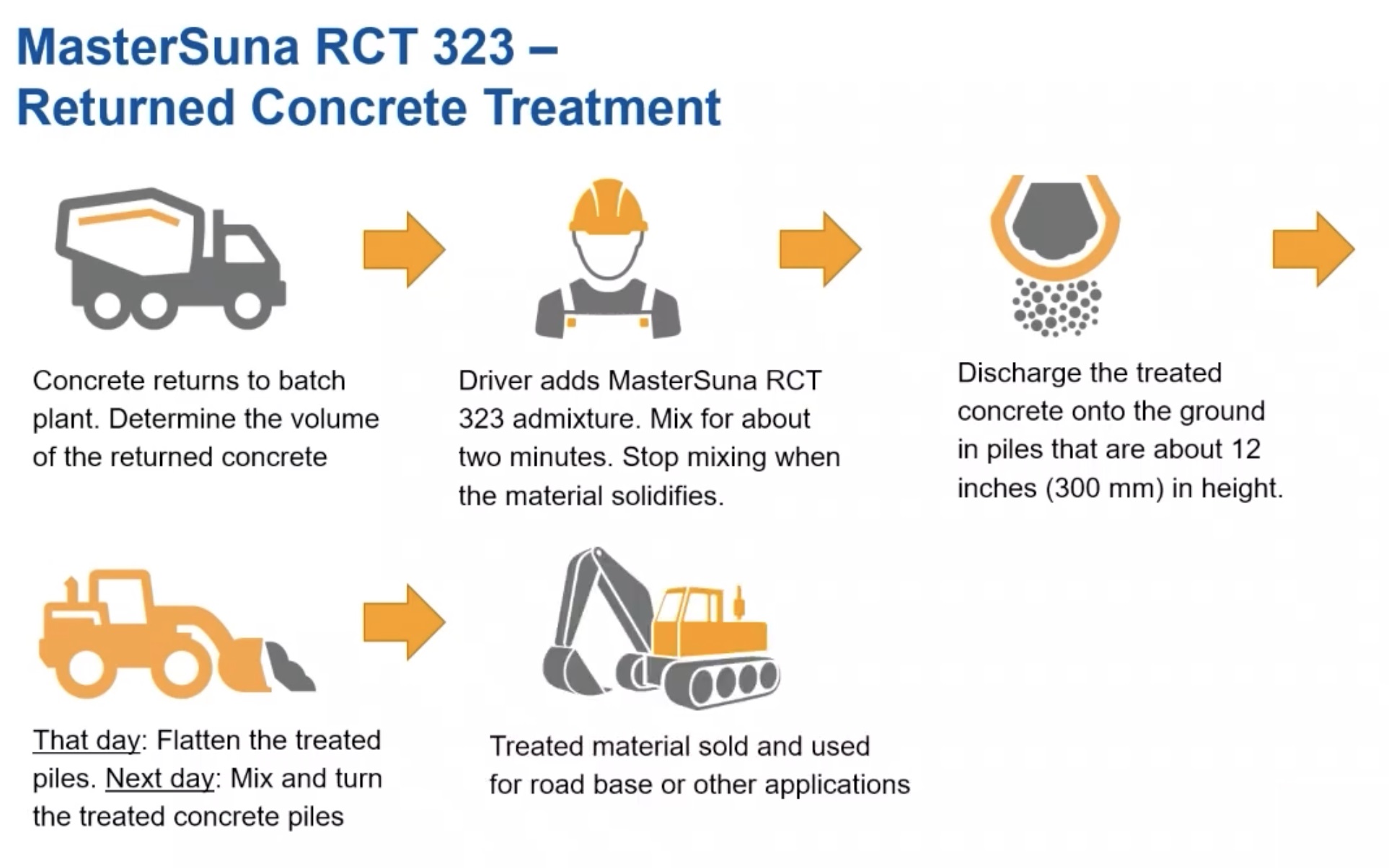

MasterSuna RCT 323 admixture allows ready-mixed concrete producers to convert returned fresh concrete into a material that’s suitable for use in road base and construction backfill – quickly, efficiently, and without the need for any additional specialist equipment.

The admixture not only eliminates the need for additional equipment to process returned concrete, but it also treats the returned concrete in the agitator drum in 75 seconds, making it extremely cost-effective in terms of equipment time and labour costs.

Jason Bolt, Executive Director – Planning, Growth and Technology with Master Builders Solutions, explained:

“While the average load of returned concrete generally only equates to one cubic metre or less, these returns can add up to a truly staggering amount of waste concrete over the course of a year – even for a relatively small, premixed batch plant.”

Returned concrete currently costs plants tens of thousands of dollars each year in disposal fees and transport. To reduce costs, labour and emissions when dealing with returned concrete, contact us