Ucrete industrial flooring - chemical resistance | Master Builders Solutions Nigeria

Thinking chemicals

Think functionality

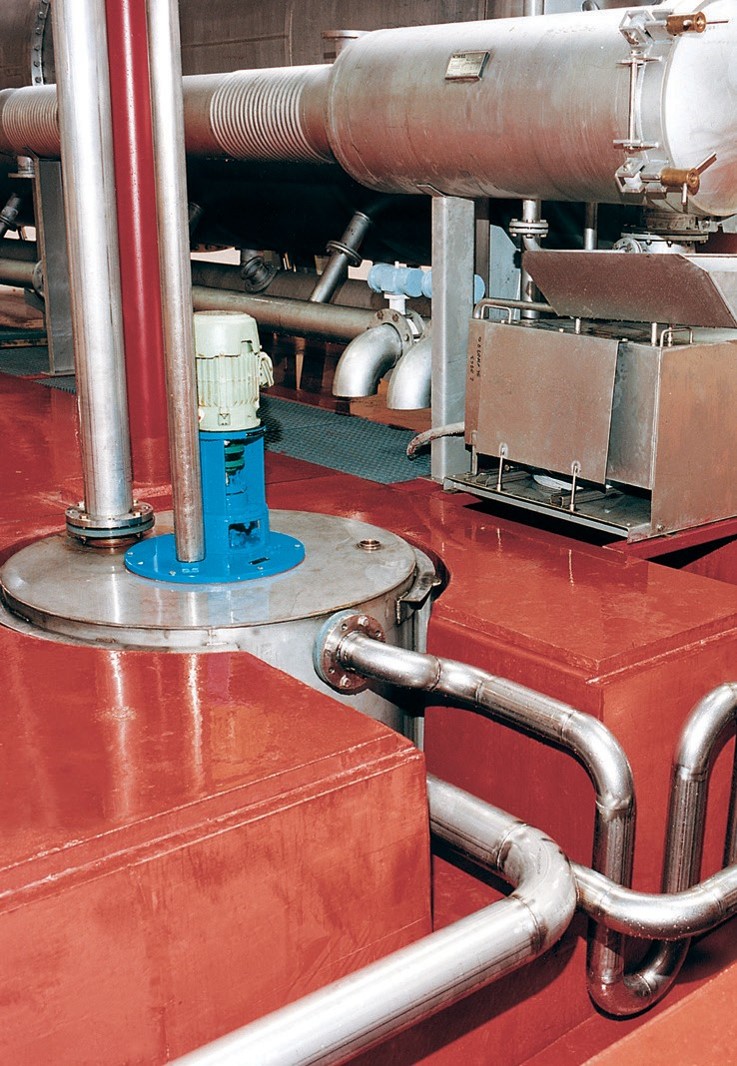

The chemical industry poses several challenges for flooring. For example, if leakage or spillage of often hazardous chemicals occurs, it must be contained until it can be effectively and safely dealt with. So floors need to be dense and impervious with the required chemical resistance, easy to clean and with appropriate levels of slip resistance

Ucrete meets these requirements, and has done for over 50 years. It is quick and easy to install, with a wide range of slipresistant profiles and a broad spectrum of chemical resistance; to acids, alkalis, fats, oils, solvents and salt solutions. This makes it the ideal flooring wherever chemical resistance is imperative.

A seamless lining

Ucrete provides a dense and impermeable surface protection system that can be used in wet and dry process areas and can also be used to line bunds, plinths, channels and drains, thus ensuring that chemicals are contained and do not escape into the environment.

For ATEX areas, too

Wherever combustible powders, solvents or gases are handled, there is a real risk of explosions. Ucrete antistatic and conductive floors provide not only the required chemical and solvent resistance but ensure that static electricity is kept under control.

Typical fields of application

For over 50 years Ucrete has been providing durable floors throughout the chemical industry. For example, in bulk chemical manufacture, electroplating, tanning, textiles, mining, heavy metal refining, household chemicals, toiletries, biodiesel production, bunded stores, wet process areas, tanker loading bays.

Thinking economically

Ucrete floors and renders are tolerant of substrate moisture and rapidly installed over a wide range of site conditions, often allowing work to proceed without the need for weather protection, thus minimizing downtime and providing the most cost-effective protective lining solution.

For detailed advice, contact your local Master Builders Solutions expert.

Think practically

Any joints in the substrate will create weak points in the protective Ucrete lining, which will require ongoing maintenance. If the joints are designed out, maintenance costs are reduced and the performance of the floor enhanced. Ground floor concrete slabs are frequently cut into 6 m bays to control the shrinkage of the concrete. Design your floor slab with adequate steel reinforcement to control shrinkage instead and the joints are gone.

Joints are frequently associated with drainage channels, for example where a Ucrete floor meets a metal channel lining or grating supports. In many circumstances, channels can be lined with Ucrete throughout, removing the need for such joints, as demonstrated at Fruit of the Loom Where joints are required, they should be located where they are accessible for inspection and maintenance.

For further information on substrate design, please contact your local Master Builders Solutions expert.