Joint design Guide by Master Builders Solutions Nigeria

All structures move. Correct design of joints allows controlled movement to occur while retaining the weather and watertight functionality of the structure. Movement occurs as a result of long term shrinkage of concrete, settlement, loading, vibration, and impact, but, the most important source of movement, results from temperature change. Even the best quality joint sealants, applied by trained installers will fail if joints are not correctly designed.

Note: Master Builders Solutions take no responsibility for design of joints. This information is provided as a guide only.

Joint design (1): joint width

The Engineer must decide on:

- the number of joints,

- the spacing and location of joints,

- the width of the joints.

This will be based on the following criteria:

- the amount of movement expected,

- aesthetic and practical considerations of the particular project,

- the movement capability of the joint sealant to be specified.

Calculation of thermal movement of a building or structural element

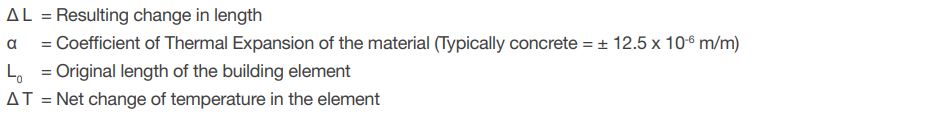

The linear movement of a building component due to temperature change is calculated using:

Example: Consider 2 concrete elements each 10 m long (see diagram below). Extreme temperatures: -5°C winter, +45°C in summer. Therefore, the movement is calculated using the equation above, as:

The minimum theoretical joint width is calculated based on the calculated movement and the movement capability of the joint sealant:

Minimum theoretical joint width = (100 / Movement capability %) x calculated movement

Therefore, in the above example, and using MasterSeal NP 472 with a movement capability of ±25% = 50% total movement capability.

Minimum theoretical joint width = (100/50) x 12.5 = 25mm

But, beware, this theoretical minimum calculation can cause significant problems if we do not consider the temperature at the time of the installation of the joint sealant, and the ACTUAL size of the joint at this time!

Consider, as an example, if the structure is built in spring at a temperature of 10°C, with the 25 mm joint width as calculated. But the sealant is not installed until late summer when the ambient temperature is then 40°C. Both the concrete elements will have expanded by 3.25 mm and the joint will have closed by 7.5 mm to an actual width of 17.5 mm. Most of the potential

movement of the joint will be as the concrete shrinks over winter time to -5°C. This 45°C temperature change will cause the joint gap to widen by 11.25 mm.

11.25 mm as a percentage of 17.5 mm = 64.3% movement far greater than the 25% movement capability in expansion of the sealant which could, over time lead to cohesive or adhesive failure either in the sealant or substrate.

For these reasons, use of a Safety factor of 2 is recommended when designing joint widths (or use twice as many joints, if aesthetics allow.

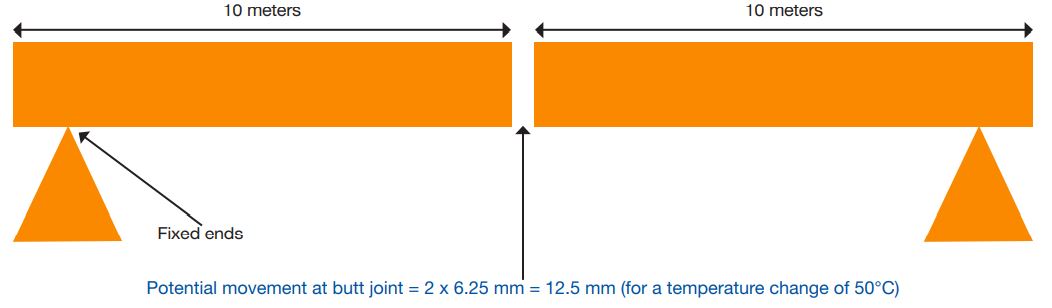

Joint design (2): joint depth

In tiling applications the minimum industry standard joint dimensions are 6 mm x 6 mm. In all other cases, practical installation difficulties mean that minimum joint widths are8 - 10mm. At these widths the depth equals the width.

However, for joints > 12 mm wide the joint depth should equal 0.5 x width.

NB: Applying sealants too deep is a major cause of adhesive and cohesive joint failure due to the excessive stresses created!

Joint Design (3): avoid 3 sided adhesion!

An essential part of joint design is to ensure that the sealant does not adhere to the base of the joint. This so called 3 sided adhesion prevents the sealant from moving as it should, and is a major, a common cause of joint sealant failures.

Master Builders Solutions Nigeria Comprehensive Waterproofing and Sealant Portfolio

- Adhesives

- Cementitious Waterproofing

- Cold Liquid Applied Waterproofing

- Concrete Protective Coating

- Joint Waterproofing and Ancillaries

- Primers

- Sealants

- Sheet Membranes

- Spray Applied Liquid Waterproofing

- Traffic Deck Systems

- Underground Construction