Sprayed concrete as a construction process

Sprayed concrete has been established and developed worldwide as a construction process for conventional tunneling. Advances in sprayed concrete technology have enabled the worldwide development of the New Austrian Tunneling Method (NATM), which was proposed during a lecture by Rabcewicz in Salzburg (Austria) in 1962, as well as the development of related construction techniques, particularly in rock in the Alps subject to high in-situ stresses. To conform with NATM principles, the inherent strength of the ground around the tunnel area should be conserved and deliberately mobilized to the maximum extent possible.

Sprayed concrete as part of the initial support system of tunnels has contributed significantly to achieving the mobilization of the ground surrounding the tunnel section. This mobilization can be achieved by controlled deformation of the ground. The use of this construction technique in rock, with maximum mobilization of the strength of the surrounding ground and continuous geotechnical monitoring, has resulted in lower loads acting on the permanent support, and hence a more economical and practical support system can be safely achieved. However, excessive ground deformation, which leads to loss of strength or high surface settlements, must be avoided.

Today it is clearly agreed that NATM is an approach to tunneling or a philosophy rather than a set of excavation and support techniques. NATM has been redefined by some institutions and some authors. New features have been added or some of its main principles disregarded to suit particular tunneling purposes or to clarify resulting conflicts. In some countries, e.g. Germany, NATM has been renamed as sprayed concrete construction process. The Institution of Civil Engineers in the UK has renamed NATM as Sprayed Concrete Lining (SCL) for soft ground applications.

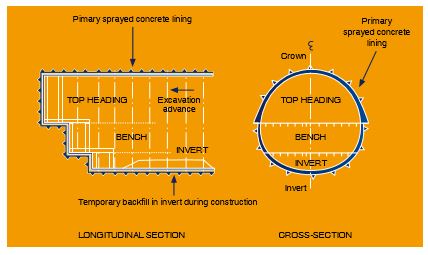

The use of SCL for tunnels in soft ground in urban areas is based on construction techniques that include sequential excavation, the application of sprayed concrete as a primary lining and geotechnical monitoring. This type of application is relatively recent, compared to its use in rock. Installation of primary excavation support in soft ground is required as soon as possible after excavation, in order to maintain stability of the excavation and in many cases, e.g. in urban areas, to limit settlement and avoid damage to overlying structures. Excavation work must be divided

into sufficiently short stages and rapid completion of primary support, i.e. rapid closure of the sprayed concrete ring is required. The performance and safety of the primary support is monitored by instrumentation to validate its design. The sequence of excavation and face areas may vary depending on the results of monitoring lining behavior.

Sprayed concrete as a construction process for conventional tunneling presents different advantages, such as:

- It provides an immediate support.

- It permits adoption of non-circular shapes.

- It allows rapid installation of structural support through the shell lining, without the use of any formwork.

- It allows reinforcement of the sprayed concrete layer by means of mesh or fiber reinforcement.

- It permits flexibility and speed in the construction of complex tunnels structures.

- The good bonding and self-supporting properties of sprayed concrete allow spraying in all directions.

Sprayed concrete may be applied to uneven ground surfaces and presents great flexibility regarding layer thickness. The following Figure 1-7 shows an example of sequential excavation based on this construction process.

Figure 1-7: Example of sequential excavation of tunnels (schematic)