PREVENT reinforced concrete corrosion, OPTIMIZE service life!

Sacrificial, cathodic protection using galvanic zinc anodes is a proven method to prevent “ring anode” accelerated corrosion around the concrete patch repair area

In the last 40 years, the Middle East has seen an explosion of construction activity in an area where climatic conditions and severe marine environments are commonplace. Chloride induced corrosion of steel reinforcement is the most common cause of structural deterioration in the existing building stock. It must be remembered chlorides can be carried over large distances which means that this problem is not isolated to beach-front structures. Indeed, the Australian Concrete society defines marine environments as any location within 1Km from the coats!

The most common procedure for repairing deteriorated concrete caused by chloride induced corrosion involves the removal of the damaged material and replacement with new concrete or mortar. While this addresses the immediate serviceability requirements, it does not always satisfy long-term durability needs as complete removal of all contaminated concrete is often impracticable.

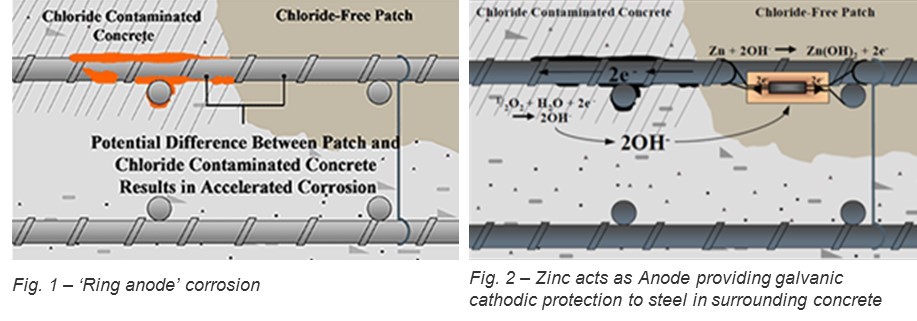

Repair of corrosion-related deterioration in concrete structures presents unique challenges. In particular, the "ring anode" effect, also called the "halo" effect (Fig. 1), is a phenomenon that is frequently overlooked but is a common cause of premature patch failure or increased repair volume. The ring-anode effect describes the acceleration of corrosion activity in the concrete adjacent to a repair area. The ring-anode effect is caused by the electrochemical imbalance between the reinforcing steel within the patch and the steel embedded within the surrounding concrete.

Galvanic Technology

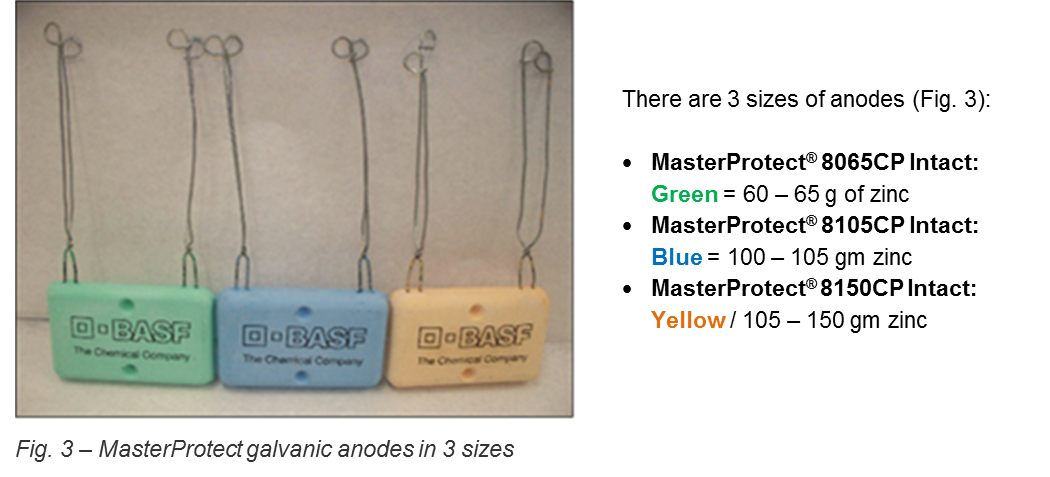

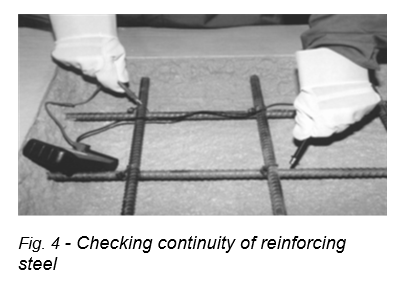

Zinc anodes have been developed to provide sacrificial or galvanic corrosion protection to the steel in adjacent concrete by preventing the formation of the so-called ring anodes. Zinc anodes are desirable because they are more susceptible to corrosion than steel. Therefore, they become the anode in the corrosion cell and sacrificially corrode rather than allowing the steel to be attacked. They create their protective current internally through a natural reaction wherein the anode corrodes to galvanically protect the reinforcing steel. (Fig. 2).

They are typically installed at the perimeter of a repair area to be as close as possible to the area of concern. When a suitable concrete or mortar is placed around the anode, it begins to sacrificially protect the adjacent reinforcement.

When to use this method?

Galvanic anodes are particularly suited for use in repairs in either chloride-contaminated or carbonated concrete when it is impossible to be certain that all contaminated concrete has been removed i.e. whenever there is a high likelihood of the formation of ring anode induced corrosion. They can also be installed in areas where potentially active corrosion of the reinforcing steel is noticed to delay corrosion damage to the concrete.

Recommended uses:- Where reinforced structures will be repaired

- Where chlorides are present in the structure

- Wherever corrosion of reinforcing steel is possible

- In post-tensioned, pre-stressed, or conventionally reinforced structures

- Interior or exterior

Repair procedure

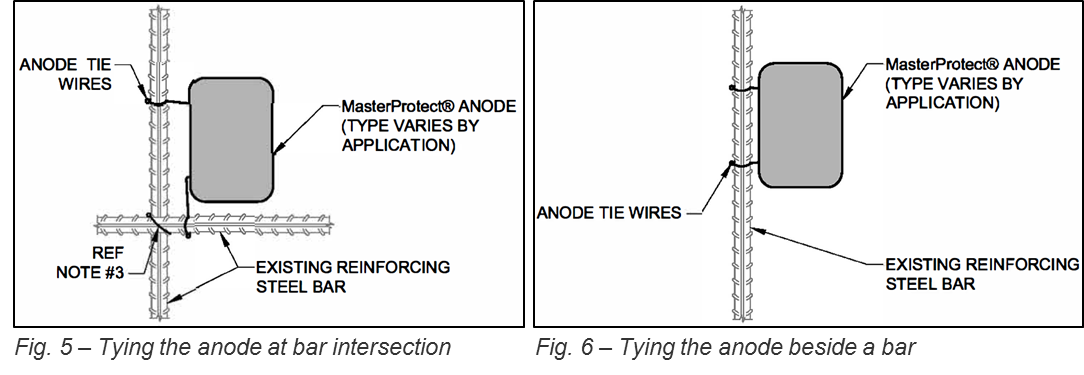

As in standard patch repairs, all deteriorated concrete should be removed from around and behind the reinforcing steel inside the repair area in accordance with good concrete repair practice. Sufficient clearance between the anode and the substrate concrete should be provided (minimum 19mm or 6mm larger than the nominal maximum size of the coarse aggregate used in the repair material, whichever is greater). The exposed reinforcing bar in the repair area should be thoroughly cleaned to a bright metal surface to facilitate good electrical connections where the anodes are attached. Prior to installation, electrical continuity of the reinforcing bar within the repair area should be confirmed with the use of a DC ohm meter (Fig. 4).

As in standard patch repairs, all deteriorated concrete should be removed from around and behind the reinforcing steel inside the repair area in accordance with good concrete repair practice. Sufficient clearance between the anode and the substrate concrete should be provided (minimum 19mm or 6mm larger than the nominal maximum size of the coarse aggregate used in the repair material, whichever is greater). The exposed reinforcing bar in the repair area should be thoroughly cleaned to a bright metal surface to facilitate good electrical connections where the anodes are attached. Prior to installation, electrical continuity of the reinforcing bar within the repair area should be confirmed with the use of a DC ohm meter (Fig. 4).

Anode choice and spacing should be determined by the engineer, and differs for each situation, with the anodes placed along the perimeter of the repair area. Spacing of the anodes is a function of steel density and the corrosiveness of the environment. Structures with heavy reinforcement or structures in highly corrosive environments will require closer spacing for the anodes to function effectively.

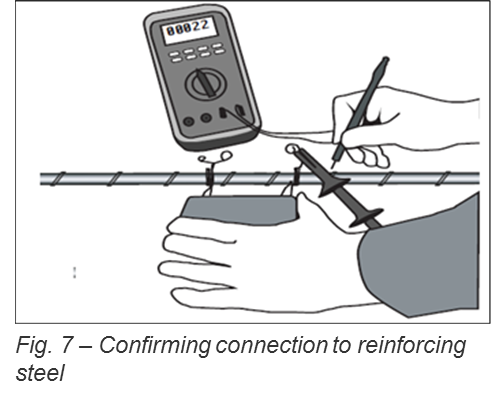

Each anode should be

securely connected to the reinforcing steel (Fig. 5 & 6). If less than 25mm

of cover exists, the anode should be placed beneath the bar (away from the

surface of the concrete). Once installed, the electrical connection between the

anode and the reinforcing steel should be confirmed (Fig. 7). The resistance of

the electrical connection should be less than 1 ohm.

Each anode should be

securely connected to the reinforcing steel (Fig. 5 & 6). If less than 25mm

of cover exists, the anode should be placed beneath the bar (away from the

surface of the concrete). Once installed, the electrical connection between the

anode and the reinforcing steel should be confirmed (Fig. 7). The resistance of

the electrical connection should be less than 1 ohm.

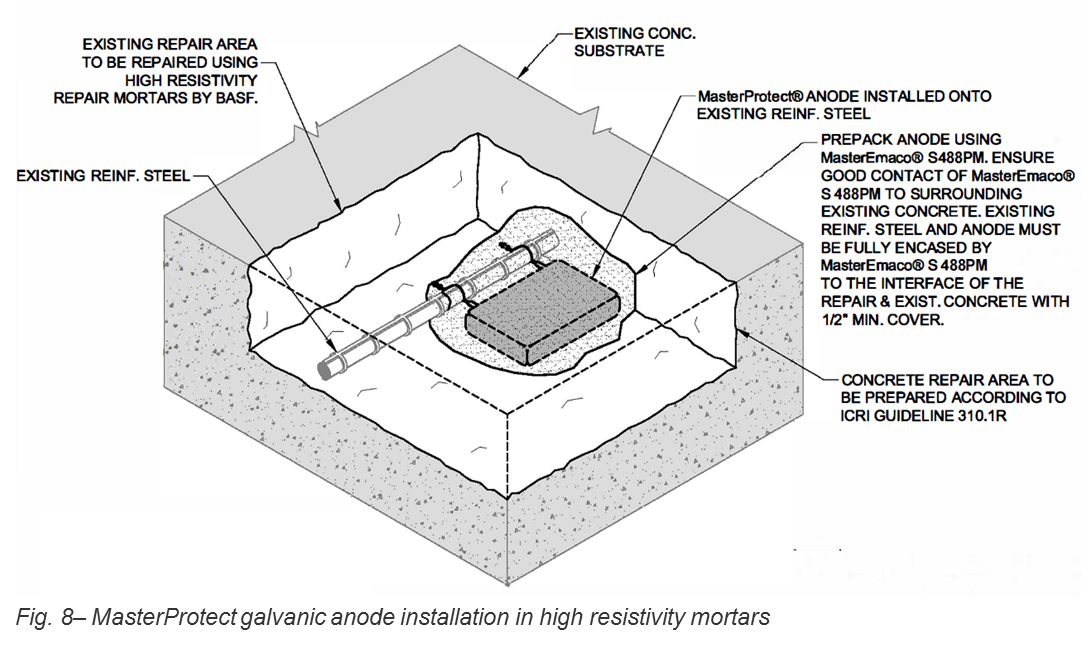

Finally, the patch cavity is made good with a compatible such as MasterEmaco S 488PM structural repair mortar using normal procedures, taking care to completely encase the anode. The anodes are designed to function properly with low resistance repair mortars < 20,000 ohm cm. Mortars should not be selected that exceed 50,000 ohm cm.

Features & Benefits of the MasterEmaco CP Intact anodes

Superior Zinc Alloy

ASTM B418 Type II zinc

- Low iron content means less intergranular corrosion and longer service life (no galvanic cell is created within the anode, which reduces its shelf life and may result in its premature failure)

- No Cadmium (superior alloy ingredients allow for the absence of cadmium without sacrificing the corrosion performance)

- Reduced toxicity

- Non-carcinogenic

- Better performance under peak corrosion load

- Less susceptible to premature passivation therefore longer service life

- More efficient because the corrosion products migrate away from the zinc

- Faster and easier to install

- Ensures proper "stand-off" from steel for optimal current throw

- Enhances the "throwing capacity" of the anode; its ability to extend its protection as far as possible into the host concrete surrounding the patch.

- Eliminates sharp corners which lead to localized stresses and potential cracks

- Faster removal of oxidation products

- Prevents passivation of anode

- Reliable performance after repeated wet and dry cycles

- Contains no lithium nitrate / bromide

- Less susceptible to job site damage

- Reduced potential for "dusting"

- Non-caustic, safe to handle

- Surface saturate when patching

- Pre-twisted wires

- Will not passivate

- Rounded Corners

References

ACI Committee E706, 2010, "Field Guide to Concrete Repair Application Procedures: Installation of Embedded Galvanic Anodes", ACI Repair Application Procedure Bulletin 8, American Concrete InstituteBehind every Master Builders Solutions innovation is a team of dedicated BASF building science experts.

Contact our sales team to learn more about this method and get a quote on your next project: Sherif Raslan