Sprayed concrete: Mix Design & Durability in the Mining Industry, South Africa

Mix Design

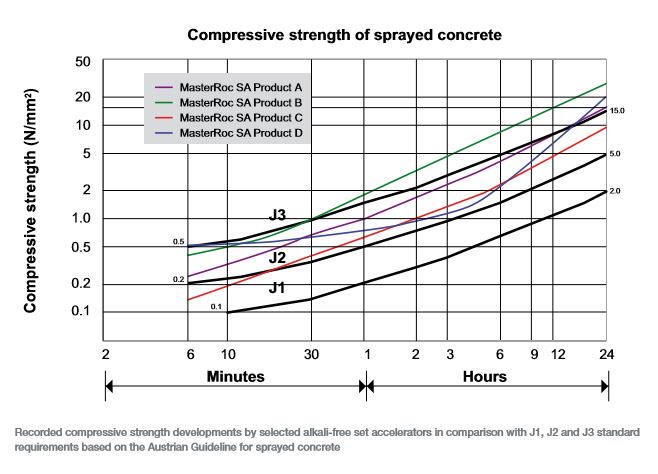

Creating the optimal concrete solution requires experienced concrete knowledge. Suitable materials for the mix (cement, aggregates, superplasticizer, etc.) and the correct alkali-free accelerator must be chosen to optimize pumpability and spraying performance. Furthermore, project limitations such as transport restrictions and badly graded aggregates, as well as specific project requirements, such as very high early strength to minimize settlement in urban tunneling and faster re-entry in mining, require a variety of admixtures to solve these specific challenges.

Durability

A durable sprayed concrete lining is defined as one that performs in the working environment for the duration of its expected service life. Achieving good durability depends on a variety of factors, especially density and water/cement ratio. Each project requires an adapted solution based on customer requirements and local building material. As a consequence of the growing use of sprayed concrete as a permanent construction material for tunnel linings, demands on its durability have increased likewise. It offers more flexibility in terms of the geometry and space requirements. Permanent sprayed concrete is a requirement for the innovative composite shell lining design