Precast Concrete Solutions

Our innovations in admixtures add value and reliability to concrete construction

Wet Precast Concrete Solutions

The wet precast method offers numerous advantages in terms of quality, efficiency, and consistency compared to traditional on-site concrete casting. Common applications of wet precast concrete include wall panels, beams, columns, slabs, architectural cladding, and various precast structural components. Admixtures are often employed to enhance the performance, workability and characteristics of wet precast concrete.

Workability Solutions:

Workability in precast concrete refers to the ease with which the concrete can be mixed, placed, and finished. Achieving the right workability is crucial to ensuring that the concrete can be properly shaped and compacted within the mould or formwork. Superplasticizers are high-range water-reducing admixtures that can significantly improve the workability of concrete without increasing the water content. They are particularly useful for wet precast concrete because they allow for better flow and self-compaction.

MasterGlenium ACE 466 - High-range, enhanced workability water-reducing admixture with rheology control and added retention benefits for precast concrete.

MasterGlenium ACE 474 - High-range, enhanced workability water-reducing admixture with longer open life for precast concrete.

MasterGlenium ACE 499 - High-range, enhanced workability water-reducing admixture with faster setting and early strength gains for precast concrete.Accelerating Solutions:

Accelerating the production and curing of precast concrete can help expedite construction projects and improve efficiency. Precast accelerating admixtures are specifically designed to speed up the curing and setting time of concrete. These admixtures can be added to the mix during batching to achieve faster strength development.

Master X-Seed 100 - Unique hardening accelerator to enable increased productivity at all temperatures which reduces hardening times, CO2 emissions & therefore lower energy costs.

MasterSet AC 555 - Set accelerating admixture for concrete especially at low temperatures.

Advanced Rheology Solutions:

Achieving the desired rheology (flow and deformation behaviour) is crucial for applications such as self-compacting concrete, high-performance concrete, structural components and architectural elements. Superplasticizers and viscosity-modifying admixtures are crucial in controlling the rheology of concrete. Superplasticizers can reduce water content while maintaining workability, while viscosity modifiers can enhance or reduce the fluidity of the mix.

MasterEase 5200 - High range water reducing admixture for precast concrete, with superior rheology, reduced mixing time and improved consistence retention performance.MasterMatrix 233 - High range water reducing admixture for concrete with unique rheology enhancing benefits.MasterMatrix SDC 100 - High-performance viscosity modifying agent (VMA) for fluid concrete to be used in conjunction with MasterGlenium ACE range (for challenging materials).

Semi-Dry Precast Concrete Solutions

Admixtures play a crucial role in the production of semi-dry precast concrete by improving its compaction, workability, durability, efflorescence and performance. Semi-dry precast concrete, falls between dry-cast and wet-cast concrete in terms of consistency and the mixes benefit from the use of various admixtures to tailor its properties. The MasterCast family of admixtures offers a wide range of concrete-enhancing products specifically formulated for the production of Semi-Dry Precast elements such as AAC, bricks, blocks, paving & roof tiles.

Compaction Solutions

Semi-Dry Precast products require careful compaction to ensure proper consolidation and the removal of air voids. Effective compaction is crucial for achieving the desired strength, durability, and appearance of precast concrete elements. Semi-dry cast concrete requires a balance between workability and compaction to achieve the desired results. Careful consideration of the mix design, formwork, and compaction methods is essential to produce high-quality precast elements.

MasterCast 281 - Compaction aid for concrete brick production.MasterCast 311 - Water reducing admixture engineered for Aerated Autoclaved Concrete (AAC). MasterCast 701 - High range water reducing compaction aid designed with enhanced strength development, particularly secondary cementitious materials.MasterCast 735 - Water reducing admixture engineered for concrete roof tile production.MasterCast 777 - Mid range water reducing admixture specially designed for use in Semi Dry Cast production process, which aids compaction.MasterCast 864 - Water inducer and finishing aid for use in Semi Dry Cast production process.

Water Resistance / Efflorescence Solutions

Efflorescence is a common issue in concrete, it appears as a white, chalky, or powdery deposit on the surface of the concrete and is caused by the migration of soluble salts to the surface. MasterPel is a specially blended admixture used to produce water-resistant and efflorescence-controlled concrete mortar. Concrete treated with MasterPel provides outstanding resistance to water migration, excellent efflorescence control, enhanced mix flowability and optimised pigment dispersion. It also reduces the need for post-applied sealers.

MasterPel 790 - Integral & surface applied water resisting admixture which reduces efflorescence for Precast concrete (with beading effect).MasterPel 793 - Integral Water resisting admixture which reduces efflorescence for Precast concrete.

Formwork / Equipment & Curing Solutions

Admixtures play a crucial role in the production of semi-dry precast concrete by improving its compaction, workability, durability, efflorescence and performance. Semi-dry precast concrete, falls between dry-cast and wet-cast concrete in terms of consistency and the mixes benefit from the use of various admixtures to tailor its properties. The MasterCast family of admixtures offers a wide range of concrete-enhancing products specifically formulated for the production of Semi-Dry Precast elements such as AAC, bricks, blocks, paving & roof tiles.

Equipment & Formwork Solutions

The MasterFinish product family comprises a range of concrete additives and form-release agents formulated to achieve an outstanding surface finish. MasterFinish solutions significantly reduce production costs through their efficiency, ease of use and superb release capability. MasterFinish admixtures also contribute to an excellent surface appearance by enabling defined exposed aggregate design or textures, as well as eliminating pinholes and other surface defects.

MasterFinish MPT 299 - Solvent free protective agent for machinery and equipment.MasterFinish RL 211 - Water emulsion form release agent for elements where excellent surface finish is important.

Curing Solutions

Precast curing compounds are materials used in the precast concrete industry to control the moisture content and temperatures during the curing process of concrete elements. The MasterKure products form a protective film over fresh concrete to retain moisture and maximise the hydration potential of the cement, resulting in optimum strength development and durability.

MasterKure 207WB - Solvent-free curing compound based on aqueous wax emulsion.

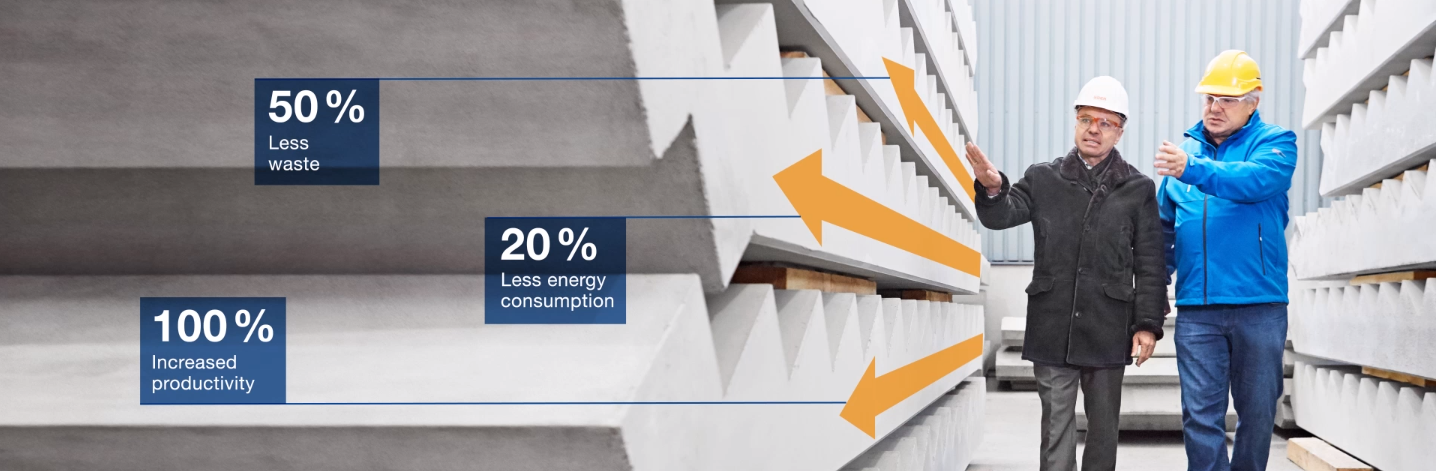

Sustainable Solutions for Precast Concrete

Sustainability in the precast concrete industry is essential for reducing environmental impact and promoting responsible construction practices. Several sustainable solutions can be applied to precast concrete production and use. These solutions aim to reduce energy consumption, minimised waste, reduce water consumption reduction of CO2 emissions and enhancement of the long-term performance of precast elements. Admixtures not only help reduce the environmental impact of precast concrete production but also contribute to the overall sustainability and performance of precast elements.

MasterCO2re - Intelligent cluster system for low-clinker concrete production.

Master X-Seed - Fast, flexible and cost-efficient production.

MasterEase - The plasticizer for efficient precast-element production

Direct contact

Brochure Download

Precast Concrete Solutions Brochure